Exemplary Info About How To Check Flatness

What are the different flatness testing methods for surface plates?

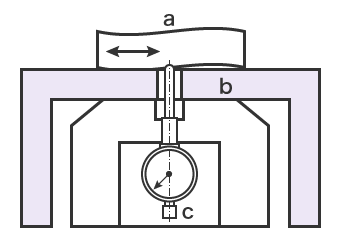

How to check flatness. Move one end in a. It will also show you the contour of the floor. There are several ways to check parallelism and flatness.

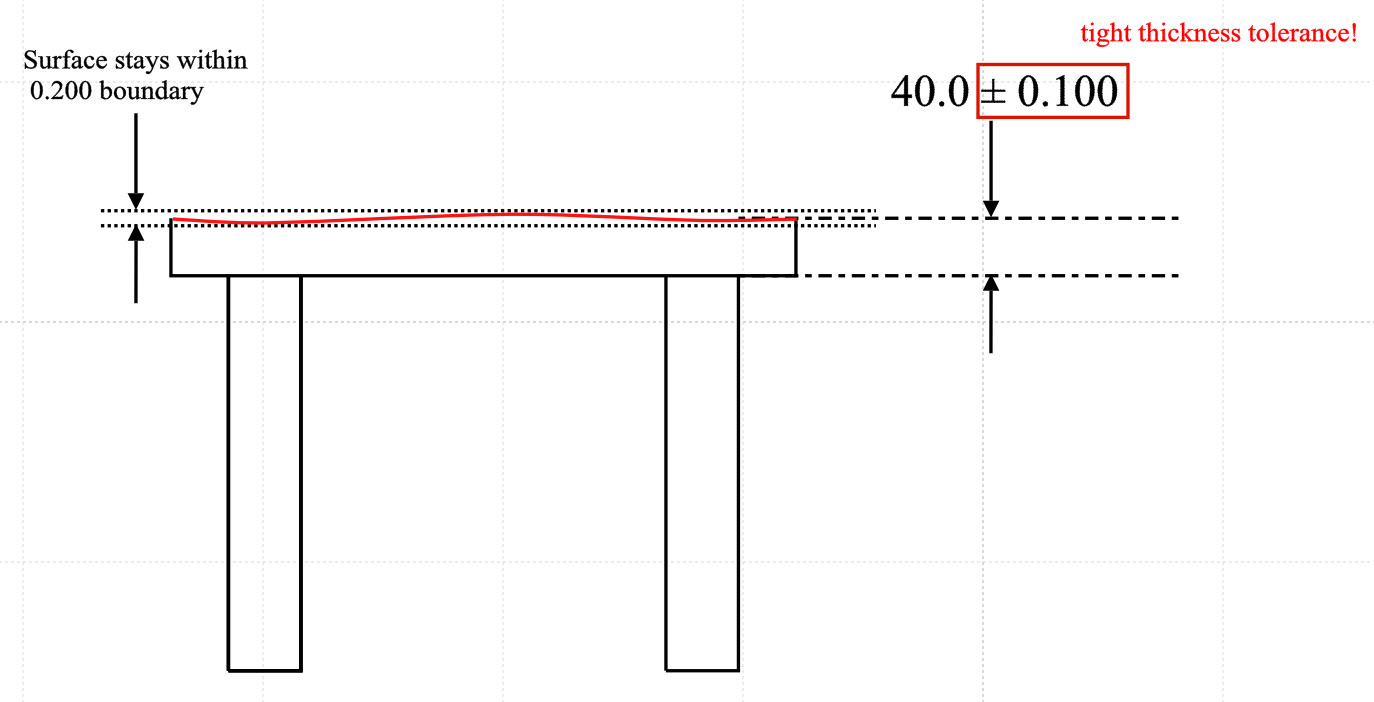

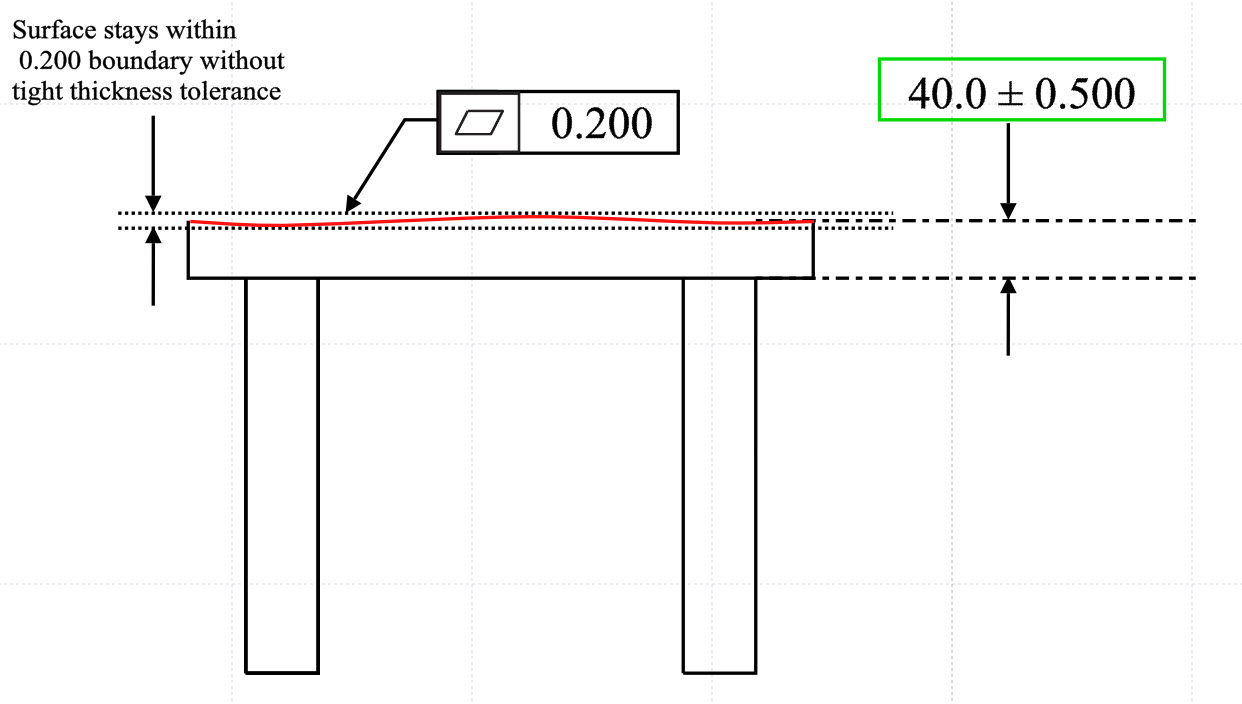

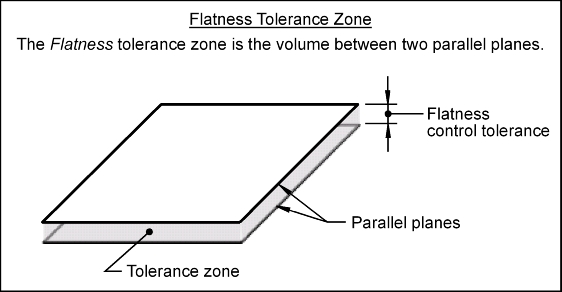

When we are measuring flatness at mmc, we are in fact measuring the flatness of the derived median plane. But, one of the possible ways to measure parallelism and flatness of the micrometer is by means of an optical flat. Flatness guidelines are 1/8 in 6' or 3/16 in 10'.

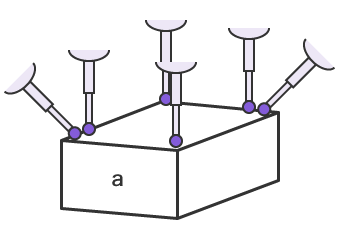

The measurement of flatness/twist on circular planes such as flanges is also based on the use of three reference points, situated at intervals of 120° around the circle. There are a number of ways to measure the flatness of a surface. First, understand that checking flatness with a cmm is not the best way to check flatness.

Feeler gauge is an instrument used to check the gap width and we check in the metric units i.e. We check the surface flatness with the feeler gauge. How to use feeler gauges and straight edges for flatness measurements.

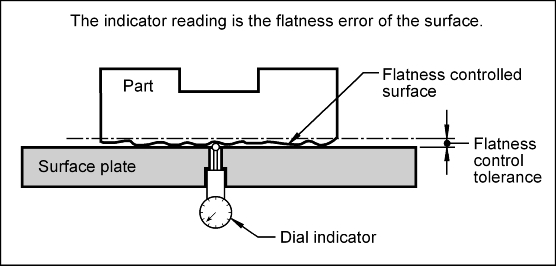

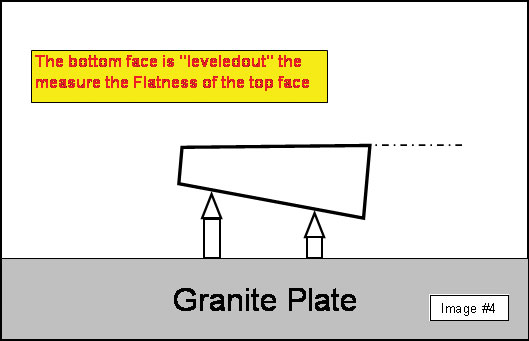

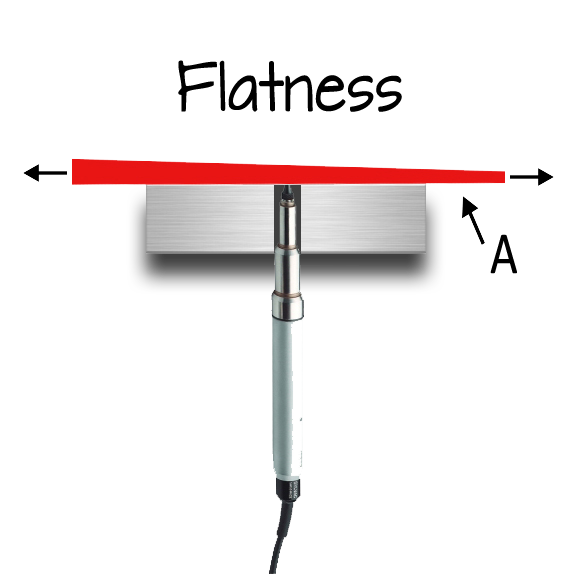

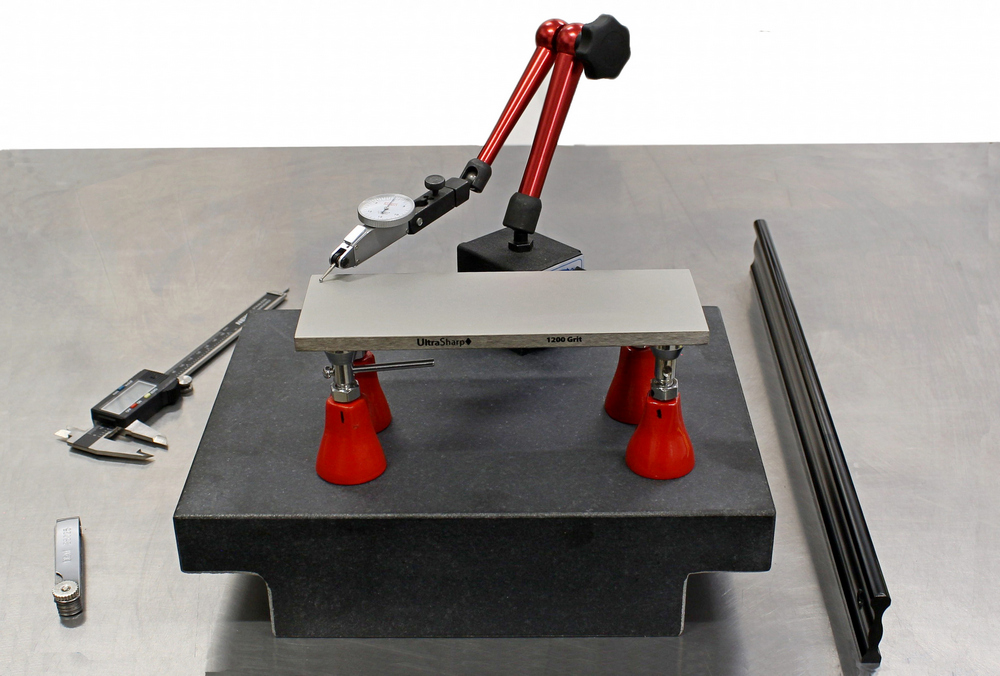

The most common method within the flat lapping sector is by using a monochromatic sodium light unit and an optical. Flatness is can be measured using a height gauge run across the surface of the part if only the reference feature is held parallel. Welcome to quality digest's new show, how to, a series for quality control and quality assurance specialists who need quick instructions on how to get thin.

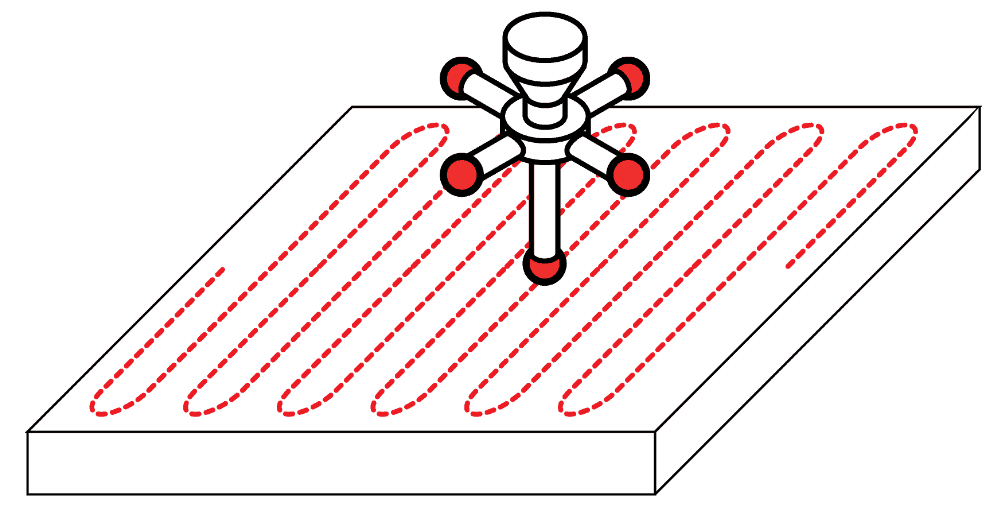

In reality, you will only be checking the flatness of the portions that the probe touches. These are the available methods for flatness testing of the surface plates. This short video shows a solid technique that allows you to check for a flat face on your faced off part, when your part is out of parallel , or a banking su.